Molten Metal Filter Boxes help produce high-quality die-cast aluminum components by using ceramic foam filters to remove impurities from molten aluminum before casting. This process ensures clean, structurally sound castings that maintain strength, finish quality, and performance through every production cycle.

For more information on how our immersion heaters support Molten Metal Filter Boxes, contact us or visit the product page.

How Ceramic Foam Filters Improve Aluminum Casting

How Ceramic Foam Filters Improve Aluminum Casting

Ceramic foam filters capture impurities as molten aluminum flows through the open-cell ceramic structure. This design traps unwanted inclusions while allowing clean aluminum to pass, resulting in smoother, more uniform metal flow and reduced casting defects. By improving the cleanliness of the melt, manufacturers see lower scrap rates and higher yield.

Sources of Impurities in Molten Aluminum

Common sources of inclusions include:

Aluminum oxide drawn in from the surface of the molten metal

Fragments from furnace linings or crucibles that loosen and enter the melt

Insoluble particles such as intermetallics, borides, carbides, or chlorides

These impurities weaken the final product and increase the risk of failure during extrusion, rolling, or forging. Proper filtration and temperature control help eliminate these issues while maintaining metal quality and reducing production loss.

Traditional Filtration vs. Modern Filter Boxes

Earlier methods like glass cloth screens and deep bed alumina filters provided inconsistent results and limited high-temperature durability. Molten Metal Filter Boxes equipped with ceramic foam filters deliver uniform, reliable filtration for both fine and coarse inclusions. They also support continuous operation without compromising temperature stability or flow consistency.

Immersion Heaters for Molten Metal Filter Boxes

Immersion Heaters for Molten Metal Filter Boxes

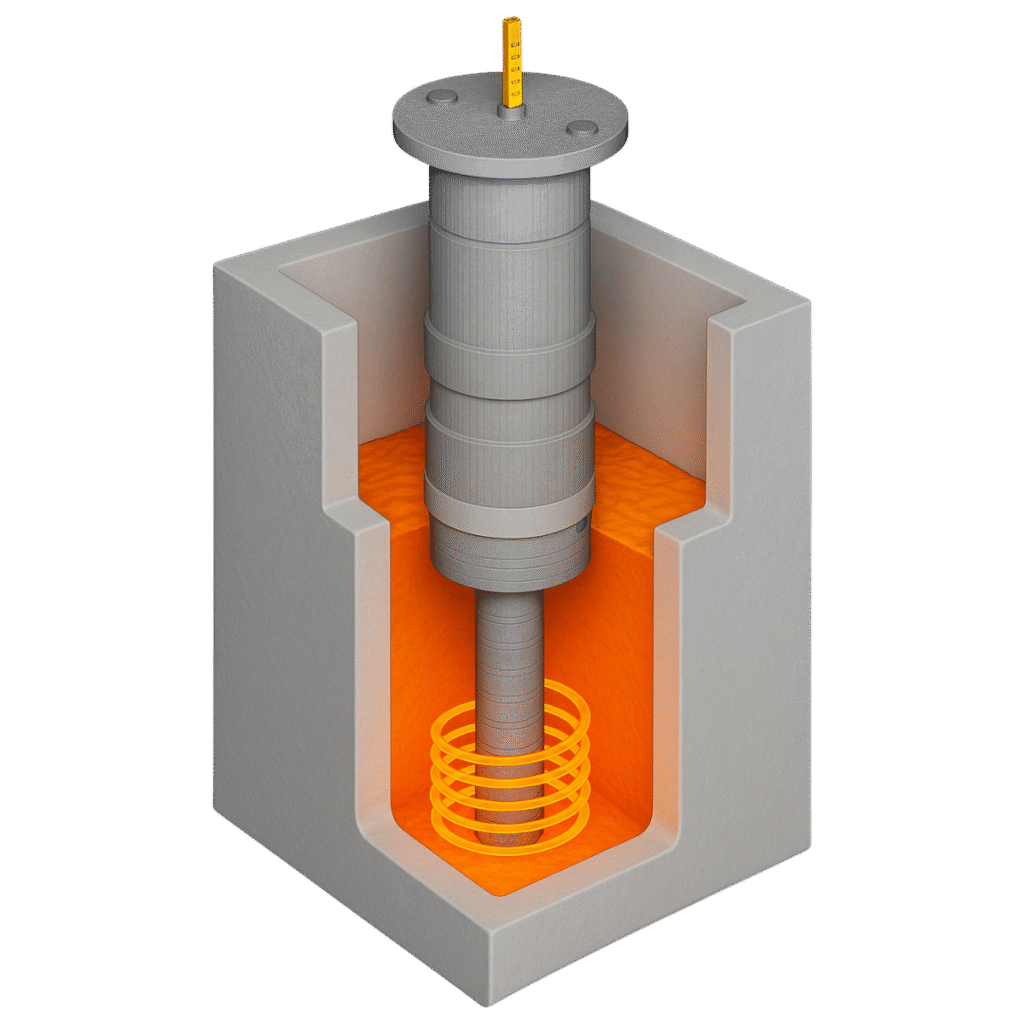

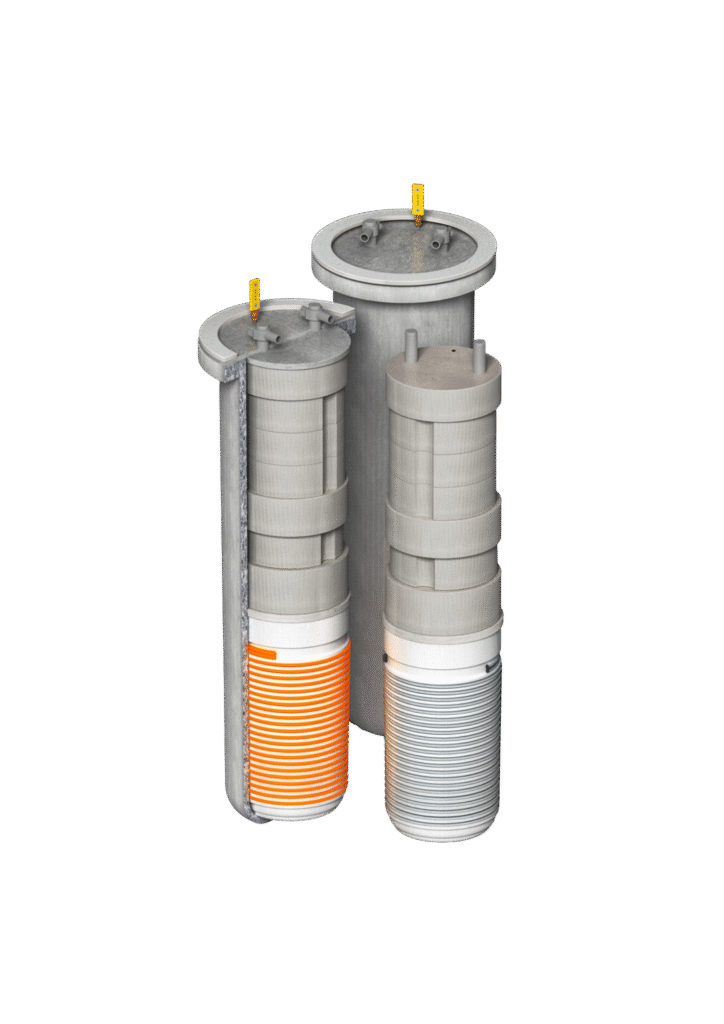

At New Century Heaters, we manufacture immersion heaters engineered specifically for molten metal applications, including use with Molten Metal Filter Boxes. Our heaters use heavy-gauge ICA wire on precision-cast ceramic cores that evenly distribute heat through dense, non-wetting protection tubes. This construction prevents coil shorting and extends heater life, maintaining consistent performance up to 2,000°F.

Our immersion heaters operate 25–30% more efficiently than glow bar or gas-fired furnaces. They help eliminate melt loss, prevent corundum buildup, and extend refractory life. When paired with Molten Metal Filter Boxes, they produce cleaner metal, faster temperature recovery, and improved casting results.

New Century Heaters offers both horizontal and vertical designs suitable for:

Holding furnaces

Degassing stations

Low-pressure furnaces

Ladle melting systems

High-purity melters

Each unit ships fully tested and supported by dedicated customer service with fast delivery across North America and Europe.

Partner with New Century Heaters

We work directly with furnace builders, foundries, and casting operations to provide the right immersion heater for each molten metal system. Whether you need single or three-phase heaters, temperature control systems, or replacement parts, our engineering team can help match your exact process needs.