Holding furnaces used in aluminum and zinc casting require controlled, efficient heat input directly into the molten bath. At New Century Heaters, we design immersion heaters specifically for these furnace environments, where temperature stability, alloy integrity, and energy efficiency determine production performance.

By placing the heating element beneath the oxide layer, we transfer energy directly into the molten metal rather than through refractory walls. As a result, furnace operators achieve faster temperature recovery and tighter process control.

View full product line of immersion heaters for holding furnaces from New Century Heaters.

Direct Immersion Heating Inside Holding Furnaces

Direct Immersion Heating Inside Holding Furnaces

First, we focus on where heat enters the system. Traditional glow bar and gas-fired reverb furnaces elevate surface temperature and super-heat refractory mass. In contrast, our immersion heaters operate inside the melt, below the oxide layer.

Therefore, hydrogen absorption decreases and surface oxide formation is reduced. Because the heat source remains submerged, energy does not need to pass through an insulating oxide barrier.

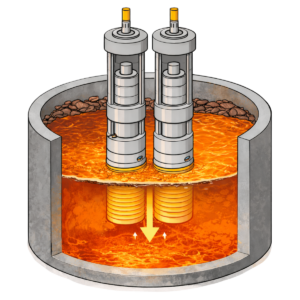

We typically position our heaters beneath a separating refractory arch and near dip wells or degassing heads. Consequently, heat concentrates in high-demand zones within the holding furnace, improving temperature stability during metal draw-down cycles.

Lower Power Requirements and Extended Refractory Life

Energy efficiency directly impacts furnace operating cost. Our immersion heating systems typically require 25 to 30 percent less power than glow bar configurations because we concentrate heat inside the molten metal instead of heating refractory structures.

As a result, electrical demand decreases while temperature control improves.

Additionally, since we do not super-heat furnace walls, refractory life often doubles compared to conventional furnace heating methods. In properly designed immersion-heated furnaces, corundum formation is eliminated, which reduces long-term maintenance and extends service intervals.

Heavy Gauge ICA Wire and Ceramic Core Construction

We manufacture our immersion heaters using heavy gauge ICA wire wound on precision cast ceramic cores. Each ceramic core contains separating grooves that maintain exact wire spacing.

Consequently, coils cannot contact one another or short during operation. This design supports:

- Even heat distribution

- Stable electrical performance under load

- Operation up to 2,000°F

- Extended service life inside molten aluminum and zinc

We recess the heating wire within the ceramic core to align with the protection tube. Therefore, we maximize heat transfer while protecting the element from mechanical stress.

High-Density Protection Tubes for Molten Metal Furnaces

High-Density Protection Tubes for Molten Metal Furnaces

Inside holding furnaces, protection tubes form the barrier between the heating element and molten metal. We manufacture high-density, high-conductivity, non-wetting tubes that resist aluminum adhesion and chemical attack.

Our vertical heaters ship pre-installed within the protection tube, and we attach mounting hardware when requested. As a result, furnace builders simplify installation and reduce handling risk.

Furthermore, our ceramic inserts pass rigorous in-house quality control testing to ensure structural stability under immersion heating conditions.

Integrated Temperature Feedback and Mounting Flexibility

Precise temperature control depends on accurate feedback. For this reason, we integrate thermocouples directly into our heater assemblies and offer multiple length options to match specific furnace geometries.

We accommodate furnace manufacturer mounting systems or provide heavy-duty mounting hardware when required. Consequently, OEM builders integrate our heaters into both inline and free-standing holding furnaces without redesigning the furnace platform.

We offer:

- Standard seal cones rated to 2300°F

- Enhanced seal cones rated to 3000°F

- Single-phase and three-phase configurations

- Heater control system support

Because we stock accessories and components in-house, we support rapid shipment when production timelines demand it.

Engineered Immersion Heating for Modern Holding Furnaces

At New Century Heaters, a Division of Senasys, we design immersion heating systems that reduce energy consumption, limit dross formation, extend refractory life, and stabilize melt temperature inside industrial holding furnaces.

By combining heavy gauge ICA wire, precision ceramic cores, and high-density protection tubes, we deliver controlled thermal input directly into molten aluminum and zinc environments.