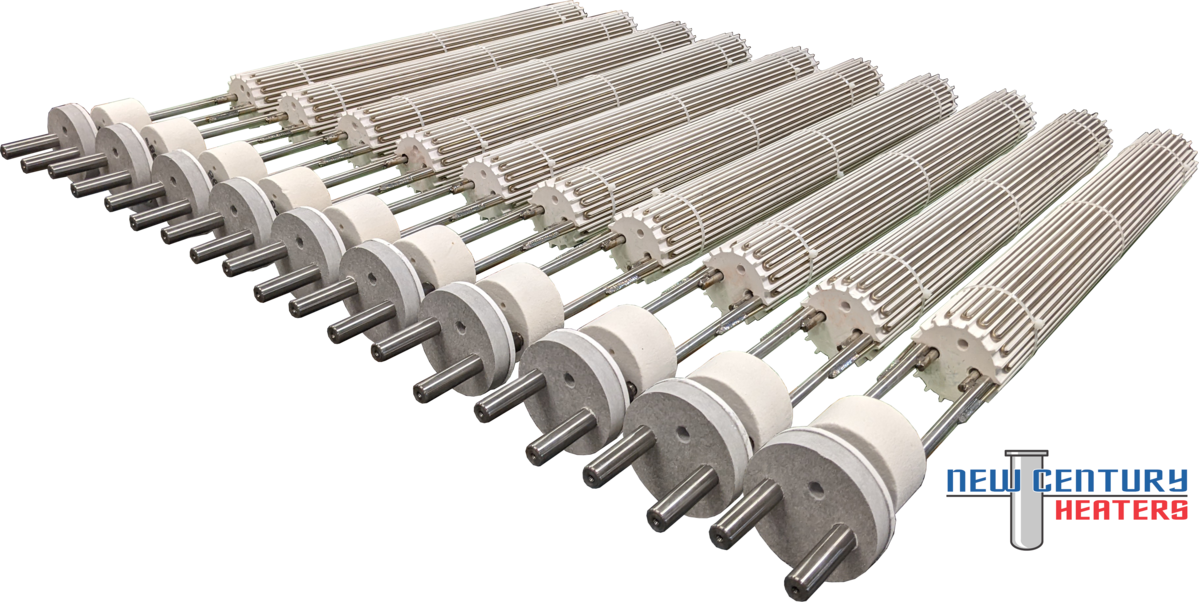

In the molten metal industry, New Century Heaters is making waves with its Cold Silicon Carbide Heating Element technology. This heating element is designed to enhance efficiency and precision in molten metal applications, offering a seamless integration of cutting-edge technology into industrial processes. In this article we will provide a step-by-step guide for introducing your cold SiC heating element into molten motel. For more information on New Century heaters SiC elements, visit the product page.

In the molten metal industry, New Century Heaters is making waves with its Cold Silicon Carbide Heating Element technology. This heating element is designed to enhance efficiency and precision in molten metal applications, offering a seamless integration of cutting-edge technology into industrial processes. In this article we will provide a step-by-step guide for introducing your cold SiC heating element into molten motel. For more information on New Century heaters SiC elements, visit the product page.

Cold Silicon Carbide Heating Element in Molten Metal: A Step-by-Step Guide

Step 1: Preliminary Suspension

To initiate the process, suspend the Cold Silicon Carbide Heater over the molten metal at a distance of approximately 10 inches above the surface. Allow it to remain in this position for a duration of five minutes, laying the foundation for the subsequent steps.

Step 2: Controlled Descent

Gradually lower the heater until the end of the tube is merely 1 inch from the molten metal, maintaining this position for an additional five minutes. This controlled descent ensures a gradual introduction of the Cold Silicon Carbide Heating Element to the high-temperature environment.

Step 3: Progressive Submersion

Continue the descent at a rate of 2 inches per minute until the heater is fully submerged. This step-by-step submersion ensures a smooth integration of the heating element into the molten metal, preventing any abrupt temperature shocks.

Step 4: Power Optimization

Manually apply 50% power initially, allowing the system to stabilize for five minutes. Subsequently, increase the power by 20% after another five minutes. Once this is achieved, the control can be transitioned to automatic mode, offering a seamless and efficient heating solution.

Introducing Heaters to the Melt after Cleaning

In another leap forward, New Century Heaters introduces a method for more effective cleaning and reintegration of the Cold Silicon Carbide Heating Elements into the molten metal.

Dross Removal at High Temperatures

Removing dross becomes significantly more manageable when the heaters are hot. Maintain the power manually at approximately 35% to ensure that the internal temperature of the heaters aligns with the metal bath temperature.

Reintroduction after Cleaning

If the power was turned off during cleaning and the thermocouples still read above 400°C / 750°F, no special precautions are necessary. For temperatures above 150°C / 330°F, lower the heaters to within 1 inch of the metal for 2 minutes before submerging them at a controlled rate of 4 inches per minute. Below 150°C / 330°F, the heaters should be treated as cold.

New Century Heaters is at the forefront of industrial heating innovation with its Cold Silicon Carbide Heating Element Immersion Heaters. As industries seek more precise, efficient, and reliable solutions for molten metal applications, our technology stands as a testament to our commitment to meeting these evolving needs.